Recognition Award Recipients

Plant Barry employees recognized for stop work participation - April 2024

Pictured L-R: Santana Salazar

- Santana was preparing to attach rigging to an 11,000lb tank that was going to be lifted by crane onto a flatbed trailer. He noticed one of the pad eyes was poorly welded on and stopped work. The pad eye was rewelded and certified by QC department.

Pictured L-R: Arturo Guzman

- Arturo noticed large cracks running up the length of square tubing that supports two staircases he and his coworkers would be utilizing during their task. He stopped work, barricaded the area surrounding the staircases, and reported the issue to his supervisor and the safety department. Client was notified so necessary repairs could be scheduled.

Pictured L-R: Freddy Hernandez

- Freddy and his crew were tasked with building a scaffold. During his JSA/TSA walkaround he noticed temporary power lines that had been run overhead placing his coworkers at risk if those lines were energized and they were to start building the scaffold. He stopped work to contact his coordinator so the lines could be confirmed as deenergized and rerouted so they posed no risk to the scaffold building crew or anyone that would be utilizing that scaffold in the future.

Pictured L-R: Timmy Wooten

- Timmy and his crew were tasked with replacing insulation and lagging. While performing his JSA/TSA walkaround, he noticed a walkway near his work area that had damaged grating and handrails putting his coworkers at risk if they had utilized that path during work. Work was stopped so the area could be barricaded off while plant safety was notified.

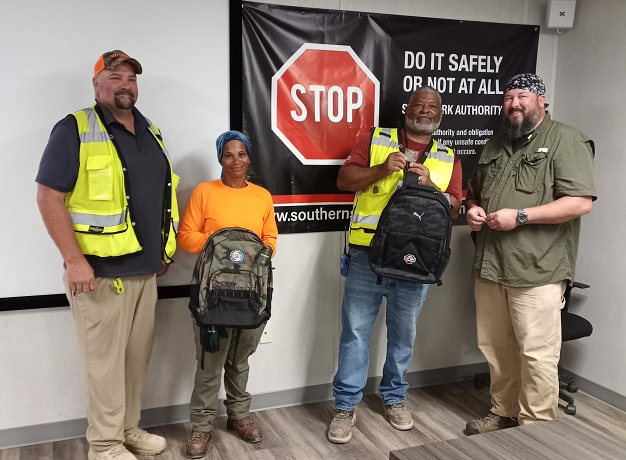

Plant Barry employees recognized for stop work participation in August 2023 - July 2023

Pictured L-R: Robert Russell (Trans Ash), Jamie Hicks (Trans Ash) and Steven Beck (SST Champ)

- Matt was observing sheet pile installation and noticed that the nylon strap being used was excessively worn. He stopped the operator and performed an inspection on the rigging. It was determined that the rigging was worn to a point of being unsafe to use. The rigging was removed and replaced before the work resumed.

- A dump truck was travelling on the ash pond and took a route that had not been watered. This produced a cloud of dust following the truck. JD stopped the truck driver until a water truck was able to adequately water the road to keep the dust from causing a visibility issue for other traffic.

- An on road vendor dump truck was backing in a load. Joshua noticed that their 3rd axle was left down as it was backing causing the wheels to turn sideways and fold over. He stopped the dump truck driver and had them raise the 3rd axle to prevent the wheels from being damaged or ripped off as it turned.

Plant Barry Stop Work Recognition - July 2023

Pictured L-R: Robert Russell (Trans Ash), Jamie Hicks (Trans Ash) and Steven Beck (SST Champ)

- Robert Russell was operating a track hoe, moving stock piled material. While operating he noticed that the cylinder pin to the bucket had become dislodged and was backing out. He stopped and parked the excavator. The maintenance crew was notified and made the repair to the pin and bucket before he resumed work.

- Jamie Hicks was operating a track hoe, when he heard a pop on his machine. He stopped and grounded the boom. Upon inspection he discovered that a weld on the boom had broken. The manufacturer was contacted and brought onsite to determine the possible cause for the failure. His action has led Trans Ash to implement scheduled master inspections of their equipment to ensure structural integrity.

Plant Greene County Stop Work Recognition - Q2 2023

CIC Employees L-R: Robert Hughes, Josh O’Neal, David Baker, James Gurganus, Stan Wilkinson

- Josh O’Neal, QA/QC, observed a sheep foot roller operator, rolling parallel with the slope. He made visual contact with the operator to approach. He gathered all the roller operators together and coached the roller operators on the appropriate direction slopes should be rolled. All operators understood the concern with rolling along parallel with the face of the slope compared to rolling perpendicular to slope direction and appreciated the coaching on proper slope rolling methods.

- David Baker, Service tech, was out in the field when he noticed one of the Dump Truck drivers standing outside the cab, while the truck was being loaded by a track-hoe. He called the driver on his radio and told him to get back in his cab and wait for him to get there. He arrived a minute later, and had the driver pull forward and out of the way of the loading area. He discussed the proper procedures and the hazards of standing outside the cab of the equipment while his truck is being loaded. The driver told him thanks for watching out for him and it would not happen again.

- James Gurganus, dozer operator, was watching one of our trucks dump a load in his area, he observed a leak from one of the hydraulic lines. Operator called the driver and told him after he finished dumping his load to pull out of the way of the other truck coming into the area, that he noticed a hydraulic leak on his truck. He called the Service Tech and had him come out to location to check the truck. Tech found a hydraulic line leaking and had the truck brought up to the front staging area where the truck received a new hydraulic line and put back in service.

- Stan Wilkinson, Foreman, was in the field when he noticed one of our new drivers exiting the cab of his equipment, while his truck was being loaded by our track-hoe operator. He called the driver on his radio and told him to get back in his cab and he shut down the loading operation and explained to him the proper procedures and the hazards of standing outside the cab of the equipment while his truck is being loaded. The driver thanked our Foreman for looking out for his wellbeing.

- Robert Hughes, Tractor operator, had just loaded tractor bucket with debris and sticks from an area that was being cleaned for placement. He went to move his equipment, one of our men working on the ground, did not move out of the tractor’s way. Robert shut down his equipment, put on his necessary PPE, and exited the equipment and coached the employee on proper procedures. Employee understood and said this would not happen again.

Plant Barry Stop Work Recognition - June 2023

Pictured (L to R): Phillip Curney (Trans Ash), JD Martin (Trans Ash), Steven Trippe (WesTech), and Nick Brekeen (WesTech)

- During the morning meeting, dump truck drivers were instructed to dump their beds that were full of rain water before beginning for the day. After the trucks were inspected several operators began to lift their beds while still at the truck line parked next to one another. Phillip stopped them and reminded that they must maintain a safe distance while lifting their beds to prevent further incident should there be a tip over.

- A water truck was making rounds around the ash pond when it came within 50 feet of a labor crew working on the ground. JD called and stopped the water truck until the labor crew got back into their vehicles to allow the water truck to pass safely.

- A subcontractor was locked on to the WesTech satellite LOTO box before starting work for the day. He added his lock to a clasp that was not properly attached to the lock box. When Steven saw it he went out and brought the employee back to show him why it was not proper and they attached the lock properly.

- Nick was asked to turn on the diesel pumps for preventive maintenance. These pumps are controlled remotely, and Nick stopped before proceeding to ask how they could be sure no one was at the pump, in danger if they turned it on. The supervisor and SCS lead had a good discussion about what the procedures are when working on the pumps in order to prevent a hazardous situation. With controls already in place, no incident could have happened, but this allowed Nick to better understand the process and know that he can always stop and ask questions to make sure there are no hazards.

Plant Barry Stop Work Recognition - May 2023

Pictured (L to R): Steven Beck (SST), William Heathcoe (Trans Ash), Tiffany Weaver (Trans Ash), and Blake Baria (Trans Ash)

- William was part of a crew that was making rounds on the ash pond, checking pumps to ensure their operation. He stopped one of his co-workers who had gotten out of the vehicle without his high-viz vest.

- Tiffany reported four stop works during the month of May. She continues to lead by example and be a model of what the stop work program is intended to accomplish onsite. She has been personally responsible for 11 stop work interventions. She has been nominated for the Southern Company safety mindset award because of her efforts.

- Blake was operating a track hoe, assisting a labor crew that was installing fabric in the bottom of a toe drain. This led them to be close to a ditch that had standing water. There was a very small space for the employees to stand between the toe drain and the ditch, which resulted in a stop work. Blake then called the supervision to discuss the need for life jackets while working close to the water. During the past two years Blake has demonstrated his commitment to his and his co-workers safety by being a leader among his peers. He has been personally responsible for 9 stop work interventions. He has been nominated for the Southern Company safety mindset award because of his efforts.

Plant Barry Stop Work Recognition - April 2023

Pictured (L to R): Steven Beck (SST), Phillip Curney (Trans Ash), DeAngelo Jones (Mersino), Tiffany Weaver (Trans Ash), Kolby Pierce (Trans Ash), Blake Baria (Trans Ash), Matt Booker (Trans Ash)

- While moving material, a dump truck was in the process of raising its bed and another dump truck began backing directly next to it. Phillip called over the radio and stopped the second truck from backing to allow space for the first truck to dump safely.

- DeAngelo was asked to get a forklift to move a pallet of material. He noticed that the forklift was parked parallel to a HDPE pipe that ran along the edge of the road. After his assessment, he did not feel comfortable moving the forklift without the possibility of contacting the pipe. He stopped and notified his supervisor and a more experienced operator was able to move the forklift with a spotter. He was recognized for making the right decision and not being overconfident.

- A truck driver was parked to go to the restroom. He was parked across the road from the restroom. Tiffany saw the parked truck and that no one was in it. She stopped and recognized the driver was walking across the haul route. She called over the radio about the man on the ground, and got his attention. She coached him on pulling off of the haul route, beside the restroom to avoid walking across the haul route.

- While setting up a water pump Kolby noticed a board lying in the area with nails protruding. He stopped and removed the nails and board before him and his crew mated resumed work.

- Employees were working to reposition water pump hoses that were full of water. An employee was straddling the hose as he went to release the ears of the hose connection. Blake stopped him and explained that the hose would shift from releasing water. They used a piece of equipment to lift the hose and drain the water before discontenting the hoses.

- A drill rig was in the process of drilling. A water truck was backed up to the drill rig providing water for the drilling. Matt noticed that there was an operator inside the truck and the drill crew was walking around the water truck completing task for drilling. He believed there was a hazard because of the truck not being chocked while other team members were walking around it. He stopped the operation until chocks were put in place on the truck to prevent potential movement.

Plant Greene County Stop Works - 2023-Q1

Pictured (L- R,) are Evan Amerson(CIC PM), Floyd Steed(CIC), Gary Woods(SoCo), Michael Spencer(CIC), Patrick Elrod(MPW), Bryan Burke(CIC), and Billy Robinson(SoCo CM).

- Floyd Steed was operating dozer and working with another dozer on pushing material. The other dozer got turned while working and the dozers were operating back-to-back. Mr. Steed stopped the operation, contacted other dozer, and explained about backing incidents and situation they were in. Second dozer saw his error and fell back in, working side by side.

- Gary Woods observed grating at Testing Platform, he noticed the grating was not attached and had slid off its brace. He stopped the testing and had it repaired by a mechanical contractor.

- Michael Spencer noticed a third-party contractor was on location installing a settlement plate instrument. A trench was excavated from settlement plate location to data logger roughly 350 feet away. Trench was not identified by third party contractor. Mr. Spencer was working in the area and observed the trench not being properly identified. The foreman reached out to safety department to call a stop work. Foreman spoke with third-party contractor and cones were put in place to identify the hazard.

- Patrick Elrod’s employer had a delivery scheduled, the Truck Driver making the delivery, did not have on PPE when he got out of his truck. Mr. Elrod stopped the driver and explained the PPE requirements to be in plant site. The driver notified the operator, that he did not have the required PPE. Mr. Elrod directed him sit in his truck while they unloaded the truck. His employer on future deliveries, will have written on Bill of Lading, notes and directions for the required PPE to be onsite.

- Bryan Burke noticed the sub-contractor's aerial lift, backup alarm was not operating. He stopped the operator on the lift. He questioned him on the alarm, and operator stated it was working during pre-inspection, but had not noticed it was not working. Mr. Burke called their mechanic over to check out the lift, and it was found that the alarm came unplugged. It was plugged back in and was put back in service.

Patrick Elrod won the drawing for 1st Quarter Site Winner

Terry Johnson Stop Work Recognition - May 2023

Pictured is Terry Johnson

- Terry Johnson was tasked with building a scaffold for lighting repairs in crusher house A. As they began to set up Terry realized that they were positioned in a way that would have the guys in danger of contacting the belt in the event of a fall. The belt was not under LOTO so Terry stopped work until the belt could be under LOTO.

Plant Miller employee recognized for stop work action - February 13, 2023

Pictured (L-R) are Michael Butts (SCS STEP Champion), Kenneth Davis (Trans Ash equipment operator), Steve Woods (Trans Ash Safety Specialist)

- While spreading a lift of fill material, Kenneth Davis, dozer operator for Trans Ash noticed what appeared to be a loose rock about midway up the highwall. The dozer operator immediately called for a stop work and radioed the roller compactor operator to move away from the highwall. The fill superintendent was then notified, and an excavator was dispatched to the area to help scale the highwall and remove the identified rock.

Recognition for stop work initiative at Plant Watson - February 13, 2023

Pictured (L-R) are Mike Gatz and Scott Boothe

- Scott Boothe with Mcabee stopped workers that just started powerwashing a floor. The exhaust fumes were getting into the work area. Scott had them move the powerwasher and brought in fans to redirect the fumes outside and away from the work area.

Plant Chevron employee exercises stop work authority - February 13, 2023

Pictured (L-R) are Mike Gatz and John Nyman

- John Nyman with Mcabee stopped work when he noticed some workers getting ready to remove a fuel oil filter for replacement near some welding work. Maintenance work was stopped until welding work was completed.

Plant Chevron employee exercises stop work authority - January 27, 2023

Pictured (L-R) are Eddie Walker and Mike Gatz

- Eddie Walker with Gulf Electric turned in a stop work when a service contractor pulled into the plant, got out of the truck with tools to start work on equipment and forgot to put his hard hat on. Eddie noticed from a ways back and walked over and stopped his work to remind him to put his hard hat on.

Employee exercises stop work authority - January 27, 2023

Pictured is Amanda Smallwood

- Amanda Smallwood stopped a crew member that was attempting to change the disc out on a Metabo while the tool was still energized. The crew was coached and taught the proper procedure for servicing any electrical tool.

Plant Watson employee exercises stop work authority - February 8, 2023

Pictured (L-R) are Mike Gatz and Chris Murr (McAbee)

- Chris Murr with McAbee stopped work while starting work in chemical house when he noticed a strange smell and saw a pipe dripping. Chris got himself and other workers out of area and notified his supervisor. Plant was notified and quicky repaired the leak.

Employees exercise stop work authority - 2023

Pictured (L-R) are LaTisha Crumbly, Dustin McPherson, Doug Arnette, Brad Anderson, Eric Johnson, Ryan McKenzie, Hieu Nguyen, Bouraima Dao, Brad Anderson

- Plant McDonough recently recognized employees for exercising Stop Work Authority. Brad Anderson and Hieu Nguyen (I&C Technicians), stopped work when they realized a contractor was working from a scaffold that hadn't been inspected. They later again exercised Stop Work Authority when they realized the contractor was not properly locked on to a LOTO prior to beginning work.

Tiffany Weaver exercises stop work authority - February 2023

Pictured is Tiffany Weaver (Trans Ash)

- Tiffany was part of a crew of dump truck drivers transporting material across the site. She noticed that two other dump trucks were in the process of raising their beds while too close together. Tiffany was able to contact the other drivers on the radio, stop them, and make them aware that they needed to better sequence their loads in order to maintain a safe distance while raising the beds of the trucks.

Jesse Turner exercises stop work authority - February 2023

Pictured (L to R) are Jesse Turner (Trans Ash) and Steven Beck (SST Champ)

- A crew was moving materials from one laydown yard to the other. A flat bed trailer was loaded with material to transport. As they began, Jesse stopped them because the load on the flat bed was not strapped down. He discussed with the crew about the unnecessary risk they were taking and the consequences of shortcuts. Jesse led by speaking up about the hazard and educating his coworkers.

Nail Davidson exercises stop work authority - February 2023

Pictured (L-R) is Nail Davidson (BVCI)

- Employee was using a table saw to cut 2x4 lumber to build forms. Nail Davidson noticed that the guard was missing on the saw. Nail stopped the employee and explained the hazards of using the saw without the required guards in place. The saw was taken out of service and the remaining saws were checked for proper guarding.

Employees exercise stop work authority - January 2023

Pictured (L to R) are Kendall White (Trans Ash), Jeremy Lott (Trans Ash) and Steven Beck (SST Champ)

- A motor grader was parked at the end of the shift and left in the travel position, with the blade elevated. Kendall stopped the operator before he left and explained how that created a hazard for entering and exiting the cab. The operator agreed and properly parked the motor grader. The instance was shared with the crew as a training opportunity the next morning.

- A contractor was entering an active work area without making the proper notifications to the equipment operators in the area. Jeremy got the contractor’s attention and discussed the proper man on the ground procedure and communication requirements for entering an active earthwork area.

Employees exercise stop work authority - December 2022

Pictured (L to R) are Charles Davidson (Trans Ash), Sanders Hopkins (Mersino) and Steven Beck (SST Champ)

- A crew was positioning a de-watering pump next to a drainage ditch after a heavy rain event. The water level was elevated in the ditch and Charles stopped the crew as they approached the edge of the ditch without wearing life vests.

- A co-worker was changing a battery on a piezometer, and was using a crescent wrench to remove the connections on the terminals. Sanders noticed that the wrench could cause an accidental arc if it were to contact both terminals at the same time. He stopped his co-worker and expressed the concern. They were able to use a shorter socket and ratchet which eliminated the possibility of contacting both terminals.

Employees exercise stop work authority - November 2022

Pictured (L to R) are Trey Lawless (Trans Ash), Eason Bexley (Trans Ash) and Steven Beck (SST Champ)

- Employee’s were walking on top of discharge piping in order to keep their feet dry in a muddy area. Trey spoke up and discussed the hazards of stepping on top of the pipe. As a result, rubber water boots were issued to provide protection while walking through the wet area.

- A fellow mechanic was using a pneumatic tool and Eason noticed a bulge in the air hose. He stopped his coworker and shut the air off to the hose. The hose was replaced and they used it as a training opportunity for the mechanic crew who regularly use pneumatic tools.

Employees exercise stop work authority - 2022

Pictured (L to R): Will O’Gwynn (SCS), Joshua Pearson (Trans Ash), Makayla Weaver (Trans Ash), with Steven Beck (SST Champ)

- Employees were preparing to remove a pump and relocate it to a different relief well. They had the valve closed to isolate the pump, but no lock on the valve. Will O'Gwynn asked about the task and recommended they stop to have a LOTO placed on the valve. The crew was thankful for Will recognizing the issue and bringing it to their attention.

- Joshua Pearson had two stop works turned in. First, he was picking up employees at the end of the shift in the site bus. An excavator operator shut down his equipment but left the excavator bucket in the air. Josh stopped him from getting on the bus and had him go back to lower the bucket to the ground. Second he was getting the bus fueled by the fueling crew. As the fueler began to fill the bus, he walked away from the nozzle while it was pumping. Joshua got the attention of the fueler and explained to prevent a spill he could not leave the hose unattended.

- Makayla Weaver was driving a dump truck when she observed a site truck run a stop sign on the ash pond. She flagged the truck down and inquired if the driver knew that they had run the stop sign. The truck driver stated that they did not see it but were thankful for being reminded. As a result, the sign was placed on a taller stand to be more visible.

John Kiper stopped work to avoid a potential fall exposure at a manhole - 2022

Pictured (L to R): Steven Beck, John Kiper (Gulf Electric), and Ed Johnson Safety (Manager BVCI.)

John Kiper noticed the ladder had been removed from a manhole, but the swing gate was left in place. This left a fall exposure if anyone were to open the swing gate. Mr. Kiper zip tied the gate shut and contacted the carpenters to fix. He then waited at the area until the gate was removed and made safe before leaving the area.

Marcus Jones stops work to avoid a potential dropped object risk - September 2022

Pictured (L to R): Steven Beck, Marcus Jones (BVCI), and Ed Johnson Safety (Manager for BVCI.)

Marcus Jones, and his crew were working on top of the HRSG. He noticed an elevated man lift basket cross over the top of his red barricade which was located on the ground under their work. This exposed the crew in the basket to a potential dropped object. He stopped and let the guys know and they repositioned the basket out of their area and thanked Marcus.

Rob Young and Chris Stowe recognized for stop work initiative - 2022

Pictured (L to R): Rob Young, Chris Stowe, Justin Brown, and Gaston SST Champion Armond Griffin

Rob Young – Inclinometer:

- A Stop Work was issued after a haul truck contacted a concrete W-block acting as a protective barrier to adjacent inclinometer instrument. The contact was minimal with no damage but it did cause a temporary erroneous reading from the adjacent instrument. Saiia held a safety stand down to make crews aware of the near miss and potential hazards. It was determined that the travel path was adequate for the haul trucks. The concrete block was positioned to better protect the instrument and painted yellow to increase visibility.

Chris Stowe – West Area:

- An operator stopped his planned excavation after he noticed an unusual odor. Site supervision and T&PS were immediately notified to investigate. Upon investigation it was determined a foreign material had been uncovered within the ash excavation. Compliance personnel were engaged for proper handling of the material. A stand down was held to reinforce the importance of stopping work and proper notification when irregular site conditions are encountered.

Martiniz Curry stops work to ensure safe work area - 2022

Pictured (L to R): Steven Beck Barry SSC, Martiniz Curry Carpenter for Vulcan, Stephen Woods Vulcan Safety

Martiniz was given a work task to build scaffold in a small, rarely used outside area of the plant. When he arrived at his job location he observed that a mid-rail had rust damage in one area, and some of the grating needed repair. He also noted the work area was cluttered, and needed some housekeeping done from a previous contractor’s work. He stopped his crew and notified his safety professional. They communicated with the SSC and contractors in the area about the hazards. They came up with a solution to secure the mid-rail and correct grating concerns. The area was cleaned up and Mr. Curry’s crew was able to proceed with their work safely.

Russell, Pearson and Hickman use their stop work authority - 2022

Pictured (L to R): Robert Russell (Trans Ash), Joshua Pearson (Trans Ash), Buddy Hickman (Trans Ash), Steven Beck (SST)

Their stop work submissions:

- Employees were fueling and greasing an off road dump truck that was loaded. Robert Russell recognized the potential for chunks of clay to fall from the dump bed onto the fuelers. He stopped the fuelers and the truck was dumped before proceeding. Trans Ash has now emphasized that the trucks beds be emptied before parking to be fueled and greased.

- A track hoe was working on a slope repairing washouts with the tracks orientated in the wrong direction. This was causing the equipment to rock back and forth when the cab would swing. Joshua Pearson, who was operating nearby, radioed the track hoe and stopped him and went over why to have the tracks in the other direction to evenly distribute the weight and prevent the rocking and potential tip over while working next to or on a slope.

- A dozer was grading an area adjacent to a new ditch that was being excavated. Water was visible in the ditch and walls and the area was saturated. Buddy Hickman stopped the dozer and called for all dozer operators working in the area to come to the location. He walked everyone through the signs he was seeing that indicated the area was too unstable to work on. Showed them examples and changed the dozer’s direction of travel to prevent a turnover in a soft spot.

Blake Baria and Trey Lawless utilize their stop work authority - 2022

Pictured (L to R): Blake Baria (Trans Ash), Trey Lawless (Trans Ash), Steven Beck (SST)

Their stop work submissions:

- A crew was applying posi-shell to sloped material while working from the top of the slope. One employee’s hard hat fell off of his head and rolled down the slope into the ditch full of water. Blake stopped him as he began to retrieve his hard hat and brought up the need for a life jacket as he would be at the water’s edge.

- Above average rain fall caused an area to flood that would normally not be under water. Trey noticed that a crew inspecting well points were now working near the water. Trey stopped the crew and provided them life jackets and a life ring. After discussion a dedicated spotter was put in place while inspecting the well points at the water’s edge.

Chantel George and Nail Davidson recognized for Stop Work submissions - 2022

Pictured Left to Right; Jim Dickey Superintendent (BVCI), Chantel George (BVCI), Nail Davidson (BVCI), and Steven Beck (SST Champ)

Their stop work submissions:

- Chantel George (BVCI) - I observed an employee tied off while standing on a scaffold but he had wrapped his lanyard around the rail and tied the hook back to the lanyard. I immediately stopped him and explained these aren’t tie-back lanyards and showed him how to properly tie off. He thanked me.

- Nail Davidson (BVCI) - I noticed coworkers flying pipe, but their tagline was too short and would require them to be under the load to retrieve the short tagline. I stopped them and suggested a longer tagline to eliminate the hazard. They agreed, changed taglines, and thanked me.

Plant Barry’s recognition of June stop work submissions - 2022

Pictured (L to R): Rodney Moore (WesTech), Adrian Hare (Trans Ash), Trevor Pafford (Mersino), Lamar Woodson Sr. (Mersino), Steven Beck (SST Champ)

Their stop work submissions:

- An aerial lift operator was positioning the lift to install piping on in a congested, tight area. The spotter on the ground said he needed to go to the trailer. While the spotter was gone, the operator continued to move the lift in the tight, congested area. Rodney was working in the area and saw the spotter leave, he heard the lift running and went to stop the operator. He then called both the operator and the spotter and had a conversation about how the lift cannot be moved without a spotter present due to the tight space.

- Adrian was working in the mechanic shop when an individual got out of his vehicle and entered the shop without a hardhat on. Adrian stopped him and reminded him of the PPE requirement. The individual had forgotten he was not wearing a hard hat and was thankful someone recognized and spoke up.

- Trevor was working with a drilling crew, when his co-worker placed himself in a pinch point. He was picking up trash when he stepped into the swing radius of the drill rig. Trevor stopped his coworker and made contact with the rig operator to stop before proceeding.

- Lamar noticed a co-worker attempting to cut plastic sheeting with a retractable blade that was dull and rusted. He approached his coworker and asked him to stop and also gave him a new blade to complete the task. They had a good conversation about keeping their tools in good condition.

Chris Holliman of Coastal Industrial recognized for stop work initiative - 2022

Left to right: Left to right: Earl Odom, Chris Holliman and Adam Hartley

Plant Daniel’s recognition of May Stop Work submission:

Chris was operating a dozer at the time when he noticed a vendor dump truck was in the process of dumping fill material on uneven ground. Chris acted quickly to get the attention of the driver and stop him from continuing to raise the dump bed. His quick action and engagement on the stop work program prevented the truck from potentially tipping over on the uneven surface.

Jesse Tuner, Blake Baria and Jeremy Lott - Trans Ash - 2022

Left to right: Jesse Tuner, Blake Baria and Jeremy Lott with SST Champ Steven Beck

Plant Barry’s recognition of May stop work submissions:

- Jesse was working with his coworkers placing seeds and hay along the dike. SWA was used when he recognized that hay had been placed over a washout which concealed the washout and could have led to someone stepping in it. Due to him speaking up the proper repairs were made to the ground, and the trip and fall hazard was eliminated.

- Blake was operating his dozer when he noticed that a dump truck had become stuck. He noticed that a track hoe operator was attempting to use the track hoe boom to push the dump truck from behind to free it. He radioed the operators to stop. The superintendent was called and brought the proper extraction equipment for the extraction of the stuck truck.

- Jeremy saw that a coworker was putting out cones at the edge of a roadway that was just completed on the ash pond. As he was walking the coworker walked too far from his guard vehicle. Jeremy radioed the other operators in the area to stop because of the man on the ground. They all stopped until he was back in the vehicle.

Derrick Stevens (BVCI) - 2022

Left to right are Nolan Gilley Safety Manager BVCI, Derrick Stevens Carpenter BVCI, Steven Beck SST Champion Plant Barry, Jim Dickey Superintendent BVCI

I noticed a coworker climbing a ladder with a drill in their hand, not tethered off. I stopped them and reminded them to secure all tools, but also suggested he use a drop bucket to hoist his tool to height. He thanked me and hoisted the tool to height. June 2022

Jarquinn Thompson (BVCI) - 2022

Left to right are Nolan Gilley Safety Manager BVCI, Jarquinn Thompson Carpenter BVCI, Steven Beck SST Champion Plant Barry, Jim Dickey Superintendent BVCI

I noticed my coworker next to me had a worn-out tool lanyard, so I stopped him and asked him to replace it. We then told the rest of our crew to stop and inspect their lanyards and get new ones if needed. June 2022

Nate Brown and Brian Seyrek, Trans Ash - 2022

Nate Brown and Brian Seyrek noticed there were people on the ground along the route where they were hauling material. Nate and Brian were able to stop all traffic in the area, by blocking the road and making an announcement over the radio. Because they were aware of their surroundings, Nate and Brian were able to ensure the safety of the persons on the ground until they returned to their vehicles.

Arturo Guzman - 2022

While insulating on the air heater expansion joint employee noticed an electrical wire smoking in conduit. He used his Stop Work Authority to get himself and other insulators down then called his Foreman and Safety personnel. They called the electricians, fixed the issue and continued insulation. May 2022

Bobby Arnold - 2022

Employee was observed using a high torque without use of hand protection (impact gloves). Work was paused shortly so that the employee could retain proper hand protection. Foreman was immediately notified, and employee coached on proper hardware and dangers for a lack thereof. April 2022

Darian Sidney - 2022

The crew was tasked with changing out a gearbox on the Unit 1 pac silo. After they removed the gearbox they placed it on the tailgate of their UTV to attempt to remove the coupling. Two EEs on the crew were attempting to remove it by one holding it with a pry bar and the other using a pipe wrench to try and break the coupling loose. Doing this put both EEs in pinch point positions. Darian stopped the work and suggested they take the gearbox to the shop where they could use the table and vise to hold the gearbox and mitigate the pinch point hazards. March 2022

Sherika Davis - 2022

Sherika was tasked with cleaning up a large water spill in the Unit 1 control room when she discovered cables with exposed ends laying in standing water in the cable spread room under the control room. She reported this to our safety department and the GPC electrical department was notified. The cables turned out to be fiber optic cables and were placed back into the cable tray. February 2022

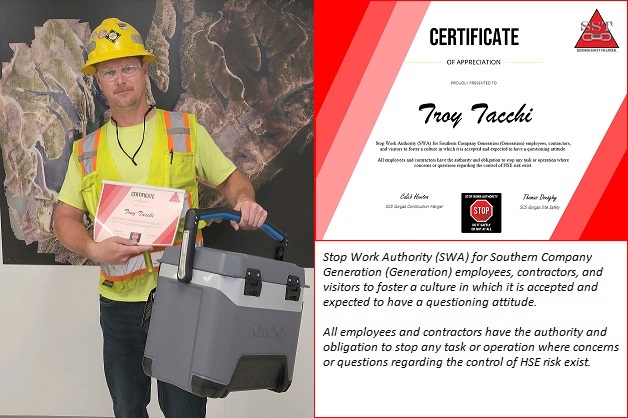

Troy Tacchi - 2022

The Gorgas Ash Pond Project would like to recognize a Troy Tacchi a Philips and Jordon Operator/ Team Member.

On April 20th, 2022 during the preparation to remove an dredge pump weighing 18,500 lbs. utilizing a crane Troy Tacchi called for a Stop Work. The lift plan previously discussed specifically called for the use of 8.5 ton shackles. While arranging the slings and installing softeners in preparation for the lift Troy observed the shackles connected by the rigging team did not appear to be sized correctly. An inspection of the shackles found them to be only 6.5 ton. The work was stopped, and the issue was brought to the attention of the Lift Director, the 6.5tn shackles were removed and replaced with two 12tn shackles. Following the shackle replacement, work resumed and the pump removal was completed successfully.

Drake Catchings - 2022

The Gaston team awarded the 1st Quarter 2022 SWA winner. Saiia employee, Drake Catchings, was presented with a certificate, SST Stop Work Champion Coin, and RTIC back pack cooler. Saiia is the prime contractor on the Gaston Ash Pond Closure project with average daily workforce of 60.

Left to right are Justin Brown, Drake Catchings, and Gaston SST Champion Armond Griffin

While a truck was offloading with bed in the air, a second truck heading to offload, rode alongside a small stockpile of materials to pass the stationary vehicle while offloading. The second truck passed within close proximity to the first truck and then proceeded to back up beside the stationary truck to offload approximately half a truck length away. We have multiple trucks in close proximity when passing in the area. Recommended to redirect traffic pattern.

Contacted supervisor to advise. Work was stopped and re-evaluated and a stand down was held for training of all truck drivers in the area. Training held to discuss proper passing and offloading procedures. New traffic pattern established to prevent the issue from happening again.

Leonard Addison (Trans Ash Operator) - 2022

Leonard Addison (Trans Ash Operator) recognized a subcontractor had entered his work area without notification and not following the man on the ground procedure. He immediately informed all drovers and equipment operators in his area to stop work until the sub had finished their task. His awareness to his surroundings and his team members resulted in a Stop Work that helped prevent an incident. Supervision was able to follow up with the sub-contractor about the importance of the man on the ground rules and proper communication.

Charles Davidson, Grant Coaker and Joseph Bush - 2022

Left to right is Charles Davidson (Trans Ash), Grant Coaker (Trans Ash) and Joseph Bush (WesTech)

Charles Davidson stopped a crew of employees who were accessing a barge to perform maintenance on a pump, when he reviewed their JSA he found did not have specific hazards of working over water noted. They were able to regroup and revise the JSA to include specific hazards and safe work methods for their task.

Grant Coaker observed two articulating dump trucks hauling material, travelling in opposite directions. The two trucks were attempting to use the same entrance ramp at the same time. The conditions were wet and slippery and could have resulted in the trucks coming into contact. He stopped the crew and they developed a better sequencing to allow safe travel across the site.

Joseph Bush was present when a vendor pump company was onsite to repair a pump. The vendor was present as the Wes Tech employee locked out and tagged out the pump. The vendor started to begin work when they were stopped and made to review the LOTO with the crew and were assigned individual locks that could be placed onto the satellite box while they were working.

Champ Steven Beck, Grant Coaker, Chase Green and Blake Baria - 2022

Left to right is Champ Steven Beck, Grant Coaker (Trans Ash), Chase Green (Trans Ash) and Blake Baria (Trans Ash)

Grant Coaker was recognized for his commitment to safety and his continued promotion of stop work authority to his crew.

Chase Green spoke up when he saw a contractor attempting to make a U-turn in a truck crane on the narrow ash pond dike road. He stopped and instructed the driver to proceed forward to eliminate the risk of turning around on the dike road.

Blake Baria stopped an employee that was beginning to move an aerial lift without wearing a safety harness. He spoke with the employee about the importance of fall protection when in an aerial lift even if he wasn't planning on going to height because of the potential to be ejected. The employee was receptive and thankful for his concern.

Chris Sasser - 2022

Chris Sasser is the Boilermaker Steward and shows his dedication by routinely helping out and this was an excellent opportunity to enlighten and educate a new employee to the site. Chris was selected as spotlight observer of the month for April.

Left to right is Champ Steven Beck and Chris Sasser

I saw a new hire placing bolts in to two buckets in a JLG. I noticed the buckets he was using were not the safety approved tool buckets that we allow at height, so I stopped him and coached him on the requirement. I then showed him where to get the correct buckets from and he thanked me. - Chris Sasser (BVCI)

Finnell "Nail" Davidson - 2022

Finnell Davidson is a seasoned employee at Plant Barry and is comfortable assisting whether it's craft to craft or in this case company to company. "Nail" as he goes by was selected as spotlight observer of the month for March.

Left to right is Champ Steven Beck and Finnell "Nail" Davidson

I observed another company preparing to work inside of an electrical sump and noticed their air monitor hose was only approximately 2 feet deep inside the sump. I immediately stopped them and asked them to reposition their hose deeper into the sump where employees were working. They thanked me and lowered the hose to keep people safe. - Nail (BVCI)

Jacob Gray, Blake Baria and Steven Beck - 2022

Left to right is Jacob Gray (Trans Ash), Blake Baria (Trans Ash) and Steven Beck (SST/Fluor).

Jacob Gray saw an employee setting up to refuel a piece of equipment and noticed he was not wearing safety glasses. He was able to stop the employee before he engaged the fuel pump and ensured he had the proper eye and face protection before he continued work.

Blake Baria recognized that a new excavator operator was tracking parallel to the ditch that he was excavating in the ash pond. With the tracks parallel to the excavation, the excavator was at risk of tilting over if the material sloughed. He was able to stop and educate the new operator about the hazard. This resulted in a refresher training for the operators on ash awareness.

Steven Beck witnessed an employee using a breaker box as a switching device for a submersible water pump. He expressed his concern about the breaker being used as a switch and the lack of appropriate PPE when dealing with the voltage. He discussed possible arc flash and shock as well. The stop work resulted in the proper weatherproof switch box being procured and used for the operation.

Norman Harris - 2022

Excavator operator was waiting on the dozer operator to clean up the haul road from ash and ruts where the trucks are backing to get loaded. While waiting for the dozer operator the excavator operator noticed the off-road trucks backing into the area where the dozer was operating. Drivers were getting too close to the dozer when the excavator operator called them on the radio and called an “All STOP” on equipment. Norman then proceeded to instruct the truck drivers on where to stage up, and he would let them know when they could resume backing operations.

Darnell Harris - 2022

Coastal Industrial’s safety pro was out in the field making a round, when he noticed the water truck driver flagging him down. He went over to talk with him about one of the off-road truck drivers following too close. The water truck driver warned the off-road truck driver that he could not see him in his mirrors, and if he were to suddenly stop, he would not have enough room to stop a loaded truck from hitting him in the rear. He told the off-road truck driver that he should stay at least 50 feet behind or far enough to see both of his mirrors so he would have adequate time to stop safely. Off-road driver told him that he understood and thanked him for watching out.

Jordan Steele and Benny Eubanks Stop Work - 2022

Two Stop Work decisions at Plant Barry O&M during week of Feb. 21, 2022

The first stop work was initiated by Pipefitter Jordan Steele. His crew was tasked with replacing several soot blowers, one at a time over the next several weeks. Jordan inspected his work area before beginning his job and discovered that there was a significant steam leak on a soot blower close to his designated work area. Knowing the danger that an intermittent discharge of steam could cause to his crew, he halted all work. Jordan got with supervision at the plant and the leaking soot blower was turned off so that they could work in the area safely. The leaking soot blower was previously set to be replaced along with the others.

The second stop work was initiated by Boilermaker Benny Eubanks. Benny was working on a mill demo job. Part of this process relies on rigging to hoist material to a staging area, where it can be removed from the building. As Benny was formulating his rigging plan, he discovered a weakness in a beam that he would have to utilize for the lift. The beam had only been tack welded at original installation. Benny was concerned that the lift would be unsafe and stopped work until he could notify a supervisor and implement a safe solution. Beam was removed and an alternate rigging point was utilized.

Phillip Drake - 2022

Phillip Drake used his stop work authority when a co-worker placed himself in a pinch point between a staged concrete bin block and a bin block the forklift was positioning in the staging area. The potential for incident and poor body positioning was discussed with the employee and crew. The SWA resulted in better planning of the task and awareness of body positioning not only for this task but others as well.

Willie Watkins - 2021

Willie Watkins from GA West receiving the coveted Stop Work Coin. Presented to him by Steven Beck the SST Champion at Barry Steam Plant and Jimmy Dunnam the site safety manager for GA West at Barry. Mr Watkins turned in a great SWA for helping a fellow craftsmen who was operating a reciprocating saw with one hand and was holding extra blades in the other. The significance of this SWA was the fact that this was craft to craft looking out for one another and sharing this with the rest of their crew the following morning in a JSA meeting. Not intended to call out the mistake for improper hand and body placement or tool use but to bring awareness and to get input from more experienced craftsmen. This is evidence of a safety culture that puts being your brothers keeper to the front line. Thanks to the whole team for the great use of the tools in place to keep everyone safe. This is where the rubber meets the road.

Pictured left to right: Jimmy Dunnam, G.A. West Safety; Willie Watkins, G.A. West; Steven Beck, Plant Barry SST Champion

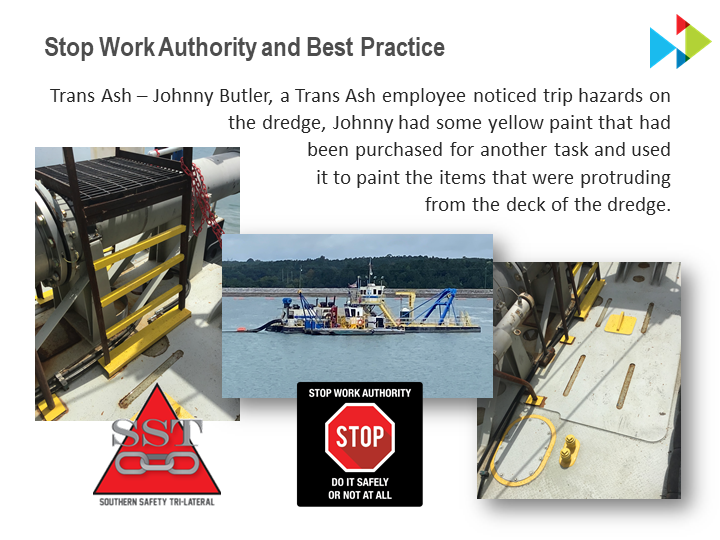

Johnny Butler - 2021

Jack Sims - 2019

On September 23, 2019. Assistant Superintendent Jack Sims was on LOTO walkdown of U-2 when he discovered that the FGD area sump flush water valve was left off LOTO as the cross over line connecting the other valve.

Pictured left to right: Tim Reynolds, Bowen SST Champion; Jack Sims, Assistant Superintendent

Nickolas Townsend - 2019

Vulcan Labor Foreman, Nickolas Townsend was performing a preshift walkdown on the work area when he smelled smoke. He discovered the 2D beltline was hanging on rollers that were not working properly. The belt was full of coal and smoking very badly. Nickolas used his SWA and pulled the emergency stop on the line and began spraying water on the belt until help arrived.

Pictured left to right: Tim Reynolds, Bowen SST Champion; Nickolas Townsend, Vulcan Labor Foreman

David Andrews - 2019

David Andrews, FMS Boilermaker Foreman, was recognized by Plant Barry SST Champion Dustin Beech and Site Superintendent Terry Ingle. David utilized his Stop Work Authority to halt a manual lift being performed using unsafe lifting techniques with sub-standard lifting devices.

Pictured left to right: Dustin Beech, Barry SST Champion; David Andrews, FMS Boilermaker Foreman; Terry Ingle, Site Superintendent

Tony Glasscock - 2019

Tony Glasscock, FMS Boilermaker, was recognized by Plant Barry SST Champion Dustin Beech and Site Superintendent Terry Ingle. Tony utilized his Stop Work Authority to halt an Aerial Work Platform, operated by an adjacent contractor, before it could be driven on to deck grating not rated for weight.

Pictured left to right: Dustin Beech, Barry SST Champion; Tony Glasscock, FMS Boilermaker; Terry Ingle, Site Superintendent

Stephen Gassett - 2019

Stephen Gassett, the acting foreman for a crew of electricians working inside the Water Treatment Plant #1, was recognized for executing a Stop Work when he observed that there were no measures in place to mitigate the concrete dust being caused by a crew of laborers drilling and chipping concrete forms to remove them. Stephen removed the crew from the area and notified the safety manager for Cleveland. The work was stopped and the proper mitigation set in place to control the concrete dust. Water was applied as the concrete chipping continued.

Pictured left to right: Tim Reynolds, Bowen SST Champion; Stephen Gassett, Cleveland; Antonio Young, Cleveland Electric Safety Manager

Tyron Owensby - 2019

Tyron Owensby was recognized for executing a Stop Work when he and an apprentice were working on a lighting project inside the Gypsum Storage Barn. A section of the Gypsum pile (approximately 15 ft) was cleared so an aerial lift could be used to install conduit along the north wall of the storage barn. Because of his concerns of a possible cave in, Tyron decided not to continue forward. He notified the foreman and the general foreman of his concerns and the safety manager was contacted. The decision was made to discontinue this project until a safer alternative could be chosen.

Pictured left to right: Tim Reynolds, Bowen SST Champion; Tyron Owensby, Cleveland; Antonio Young, Cleveland Electric Safety Manager

Robert Johnson - 2019

Robert Johnson recognized for executing a Stop Work when he and the rest of the crew were inspecting the rigging and he noticed something didn't look right, so he asked the foreman about it. The foreman deemed that the nylon sling needed to be tagged out.

Pictured left to right: Robert Johnson, Brad Cole; Daryl Abrams, T&PS

John Paul - 2019

John Paul recognized for executing a Stop Work when he observed an employee was incorrectly using a grinder on tungsten. The employee had the grinder chained down to a pipe tripod, with the trigger being engaged by the chain on the tripod itself.

Pictured left to right: John Paul, Zachry Construction; Mario Guzman, T&PS

Jerry Hendrick - 2019

Jerry Hendrick recognized for executing a Stop Work when he observed a 35-ton crane was set in place without proper outrigger pad coverage making sure that full bearing pressure on the ground was established.

Pictured left to right: Jerry Hendrick, Zachry Construction; Lloyd Kern, T&PS

Richard Horne - February 2019

Richard Horne is awarded the SST Safe Worker recognition award for executing a Stop Work while working at Plant Scherer. Richard observed a contractor employee reaching half of his body inside of a Fusion Machine without having the machine shut off as per manufacture manual. This information was discovered once the CCR Project Management requested the operators manual of the equipment.

Pictured left to right: Marty Mingus, SCS ASM; Richard Horne, SCS QA Coordinator

Sam Harris - January 2019

Plant Scherer employee, Sam Harris, receives the SST Safe Worker recognition award for executing a Stop Work when he observed a piece of pipe being flown over an employee's head who was working on a suspended scaffold. Additionally, he observed a rigger standing directly underneath a piece of pipe that was suspended from a crane and chainfall.

Pictured left to right: Marty Mingus, Sam Harris

Terry Bell - November 2018

Fluor employee, Terry Bell is awarded the SST Safe Worker recognition coin for executing a Stop Work while working at Plant Gaston. Terry observed another contractor preparing to lift a heavy beam for the air preheater monorail support system using beam clamps in an incorrect manner. Work was stopped, and the beam was rigged properly before the lift took place.

Pictured left to right: Kyle Burgett, Fluor Alliance Manager; Terry Bell, Fluor Site Manager; David Murphy, Fluor Executive Director